VERTICAL PRODUCTION

VERTICAL PRODUCTION

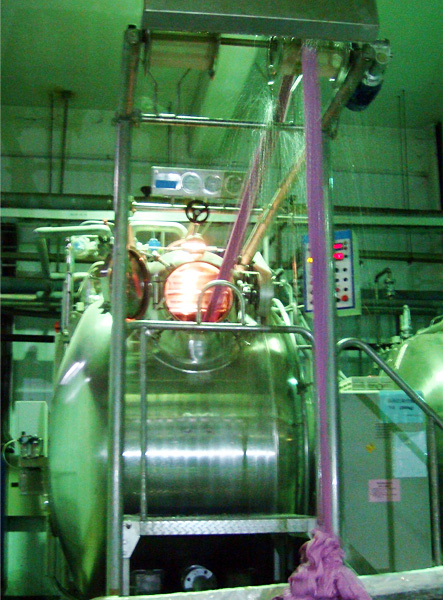

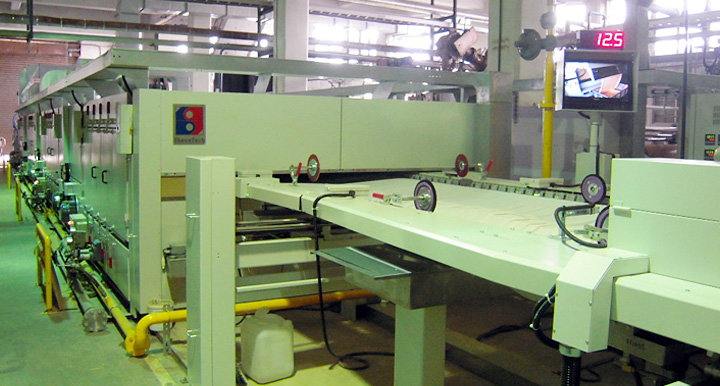

Before 2005, textile industry played an important role in contributing exporting business in the economy of Taiwan. After WTO ATC textile quotas in the global market were abolished in 2005, textile industry faced higher competition and challenges. It means that we lost labour-intensive production, mainly garment and accessories. This resulted in the broken of clusters of textile production. As a knitting company, it is more difficult to find the business partner to dye and accomplish the fabrics completely. In the face of challenge in the international markets and transformation of the domestic industry, we BEBE COTTON decide to involve the dyeing & finishing processes by establishing a new facility in Da Yaun. By integrating our sustainable operation, we could do pattern designing, knitting, dyeing and finishing processes vertically on our own.

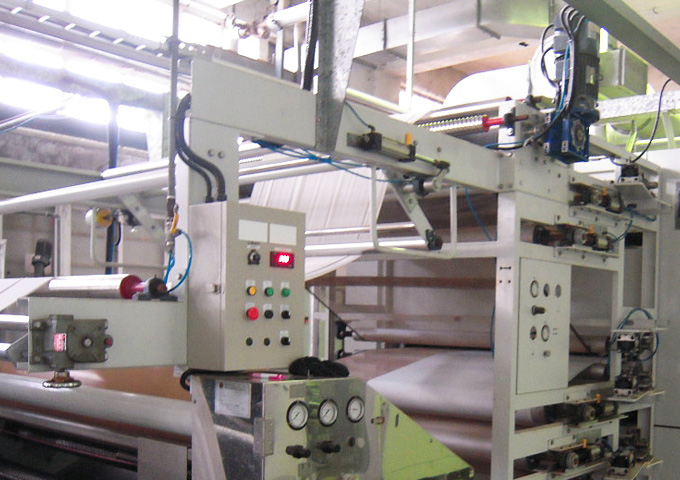

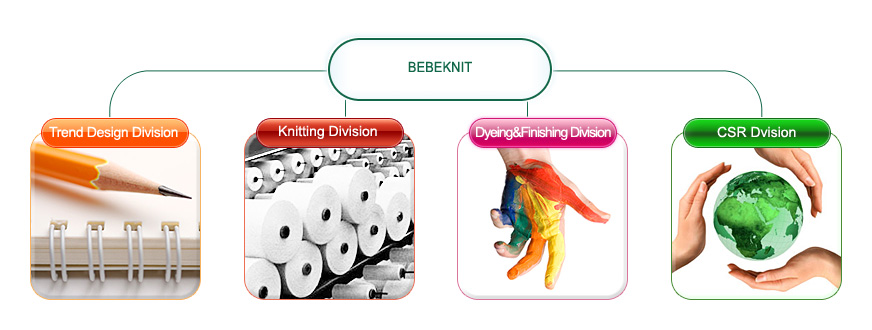

To meet customers' demands and provide excellent fabrics, BEBE COTTON will maintain the production standards and continue to upgrade machines to provide high quality and stable fabrics. Now we have 4 divisions in our production lines:

Trend Design Division

Knitting Division

Dyeing & Finishing Division

CSR Divison

Taipei Innovative Textile Application Show 17-19 October 2016

Taipei Innovative Textile Application Show 17-19 October 2016 Munich Fabric Start 30-01 August 2016

Munich Fabric Start 30-01 August 2016